This clamping system minimizes setup times, enable a machine to access five sides of a part and provides highly repeatable positioning for bulky components.

Sometimes, a shop’s efforts to become more effective at machining results in a marketable product line. This was the case with FCS Moulds, now Elmann S.R.L.U.

The Italian moldmaker sought to develop a standard means of fixturing mold components that would minimize setup times, enable its machines to access five sides of a fixtured part, and provide highly repeatable positioning so parts could be removed and accurately refixtured at the same zero reference points as needed. Ultimately, its goal was to increase its machines’ spindle utilization so it could be more competitive with foreign moldmakers.

The FCS modular clamping system was invented by the company’s Almerino Canuto in 2003. After successfully applying this system for its own use, the company formed FCS System to offer the solution to other shops hoping to realize similar benefits. FCS has been available in the United States for a few years through Single Source Technologies (Auburn Hills, Michigan), its exclusive U.S. distributor. Darrell Johnson, SST product manager—milling consumables, says shops that use FCS have sped production time by an average of 88 percent. This workholding solution is particularly helpful for shops machining large mold components as well as other big, unwieldy parts that are commonly tough to set up, such as those used in the fracking industry.

The foundation of FCS is a base gage plate that mounts on a machine’s table. This plate has a grid of threaded holes spaced 50 mm apart to within 5 microns of each other. The other primary components are shown in the image to the left. Mr. Johnson says the system’s rings are key to achieving micron-level positioning repeatability. One side of the TiN-coated steel rings installs into a mating profile machined into the workpiece, achieving an H7-class fit. The other side of the ring has a precision-ground taper that fits into a cylindrical clamping body.

A rod connects the clamping body to the workpiece. One end of the rod installs into the workpiece with standard metric threads, typically M12 × 1.75 or M16 × 2.0. The serrated feature on the other end of the rod fits into the clamping body and draws in the workpiece when tightened, guiding the taper on the ring between them into its precise location.

On the other hand, Mr. Johnson says advanced adopters of this workholding method take advantage of the optional Guideline software, another distinguishing element of this workholding approach. Developed by Italy’s BKC, Guideline software enables users to create an appropriate workholding system based on a CAD model of the part to be machined and models of standard FCS fixturing components. The software analyzes the workpiece model and automatically determines appropriate fixturing points while checking for possible interferences with other holes. The software can also automatically generate a bill of materials for the individual FCS workholding elements needed for the application.

UNIQUE THREAD-FORM TAPS FOR HIGH-VOLUME CNC PRODUCTION

Machinists now can add a locking feature to tapped holes by using specialized and newly refined Spiralock taps from Stanley Engineered Fastening, Shelton, CT, optimized for extended tool life in high-volume CNC operations. The taps are based on a unique thread form that resolves the thread-loosening and joint-integrity problems common to standard fasteners.

In traditional 60-deg. threads, the gap between the upper edges of the male and female threads can lead to vibration-caused loosening. Stress concentration and fatigue at the first few engaged threads also can be a problem. The unique profile of Spiralock threads closes the gap that causes loosening, improving the integrity and reliability of threaded joints.

Thread-form tapping has traditionally been a relatively slow machining operation, due to its limited visibility and necessary precision. Not content to let tapping technology become stale, Stanley Engineered Fastening has improved its lineup of machine taps by enhancing the tool’s geometry, surface coatings and flute angles, as well as shapes and nose size. These improvements promise to enable higher-speed production and significantly extend tool life. PVD coatings enable tapping as much as 50-percent faster than with previous nitride or bright finished taps, and help the taps to cut smoothly in deeper holes where there is little coolant or lubrication. Also available: a dual-layer PVD coating.

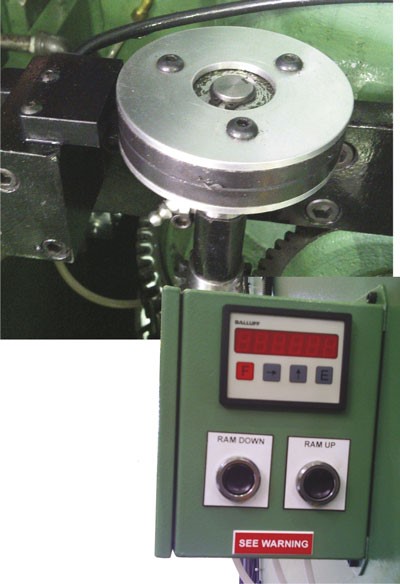

ADVANCES IN DIE PROTECTION AND IN-DIE SENSING

There is a premium on manufacturing experience. Trying to hire someone with the skills needed to design, build or maintain automated manufacturing equipment is a difficult task for every HR department across the country. We must work to make manufacturing interesting.

In addition, investing in the education of existing employees represents an investment in productivity. To remain competitive, U.S. manufacturers have embraced automated manufacturing, and sensors sit on the FRONT LINE of any automated system. Sensors provide intelligence to the system, and they take a beating when improperly installed. Even worse than a destroyed sensor is a sensor installed improperly in a stamping die, which undoubtedly will cause a misfeed or die crash at some point in the life of the tool.

A recent incident at a manufacturer in the Southeast United States illustrates the importance of well-implemented in-die sensing, and what can happen without it. Due to a combination of misfeed, bad timing, poor shut-height setup and other factors, the connecting arms to THE RAM on a 500-ton press were bent beyond repair. And, the mechanicals in the entire press and half of the tooling were destroyed. The press was sold for scrap.

Forward-thinking manufacturers focus on the goal of staffing their press shops with well-trained technicians and die builders. INVESTING in your die builders’ education is an investment in die protection.