Machine-embedded, IoT sensors will not only monitor machinery for weakness, but they will also enable machinery to fix itself automatically, researchers say.

Production downtime’s days are limited thanks to the industrial Internet of Things (IoT). Machine-embedded, network-connected sensors along with the collection of massive amounts of data will allow for self-healing manufacturing, scientists say.

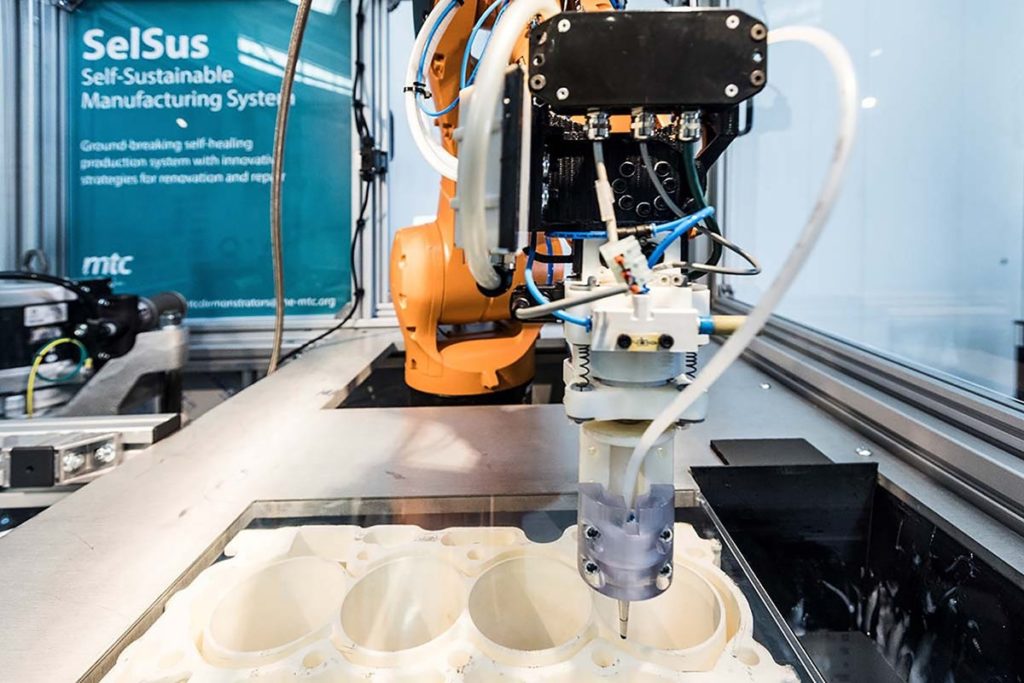

That’s the concept behind an enthusiastic research project called SelSus currently being explored by multiple European academic institutions and manufacturers, including Ford.

The idea that the team proposes is to not just detect weaknesses during production, but to also fix the potential issues automatically through a kind of mathematically calculated self-healing. The scientists say diagnostics should supply recommendations before a piece of equipment has failed. That self-healing aspect would take equipment monitoring to the next level.

“The aim is not just to monitor the status of the machines and components,” says Martin Kasperczyk of Germany’s Fraunhofer Institute for Manufacturing Engineering and Automation IPA, one of the participating organizations, in a press release. “The plan is to detect potential weak points or signs of wear and tear early enough for the system to be able to predict potential malfunctions.”

It should also correct the defects, too, in some cases.

The team has already gotten some of that to work. With one of the EU-funded research partner’s systems — a robotic arm for engine production — the device will self-heal when it starts to fail. If it were to detect resistance, for example, it would back-off rather than snap, the researchers explain.

The system can also calculate the probability of a stressed cable breaking under load.

How the self-healing technology works

Mathematical models called Bayesian networks that compute probabilities are behind the networked sensor-driven tech used. It, along with learning software that analyzes how the machine should run compared to how it is actually running, is part of the algorithm makeup.

It hasn’t been easy, though.

“You don’t get there just by programming a couple of algorithms,” Kasperczyk says.

Model data is captured during machine setup and also in a test under load. It’s then compared to actual running conditions, along with an alert to human machine operators.

“The major challenge is building up the models both for decision making and simulation in a way that they reflect the real manufacturing environment,” says Fraunhofer IPA’s Michael Kempf on the project’s website.

I’ve written about other kinds of IoT machine-failure sensing before. Sound monitoring sensors, connected to IoT can predict mechanical failure. Ultrasonic and vibration-sampling sensors, along with algorithms, can advise operators that there’s trouble ahead based on the noises the machine makes — it won’t sound right if there’s an anomaly.

One of the players in the SelSus (Health Monitoring and Life-Long Capability Management for Self-Sustaining Manufacturing Systems) project is Swedish home appliance maker Electrolux. It wants a decision-support system to predict failures in its laundry washing machine manufacturing plant. Sensors monitor excessive power use, heat generated and machine oil usage. They are all indicators of trouble. The number crunching provided by the SelSus project should ultimately keep the plant running all of the time.

“Often the problem is only a small defect or normal wear and tear. However, if left undetected, these can lead to major disruptions and production downtimes,” SelSus researchers say.