CNC milling is a CNC process that involves the use of rotating cutters to remove portions of a block of material (or workpiece) till the desired custom shape (or feature) is made. It allows manufacturers to create intricate parts accurately while meeting tight tolerance requirements.

CNC milling is a CNC process that involves the use of rotating cutters to remove portions of a block of material (or workpiece) till the desired custom shape (or feature) is made. It allows manufacturers to create intricate parts accurately while meeting tight tolerance requirements.

Computer numerical control (CNC) milling machines have evolved over the years, allowing for the creation of precision parts that meet the stringent requirements of today’s demanding industries. The applications of CNC milling machines are near-endless, spanning across many industries like the aerospace, automotive, robotics, and medical industries, to name a few.

Computer numerical control (CNC) milling machines have evolved over the years, allowing for the creation of precision parts that meet the stringent requirements of today’s demanding industries. The applications of CNC milling machines are near-endless, spanning across many industries like the aerospace, automotive, robotics, and medical industries, to name a few.

This article will get down to the nitty-gritty of CNC milling. Do you want to know about the milling process? The types of milling operations? The advantages of the process? You’ve come to the right place.

What is a CNC Milling Machine?

To understand what a CNC milling machine is and how it operates, let’s get back to the basics of milling. Milling is a machining process that involves the use of rotating cutters to remove portions of a block of material (or workpiece) till the desired custom shape (or feature) is made.

Conventional milling machines typically feature a moveable tabletop (or clamping device) that holds the workpiece in place, allowing machine operators to move the workpiece in different directions against the rotating cutter.

Like the conventional milling machines, CNC milling machines also rely on a moveable tabletop and rotating cutters to remove materials and create parts. However, they differ in the mode by which these machining operations are carried out.

CNC milling machines use computerized controls to carry out machining operations, whereas conventional milling requires manual operation of the rotating cutter to create parts.

The CNC Milling Process

We can divide this process into three stages.

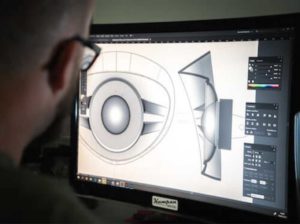

Stage 1 Create a 2D or 3D CAD Model

The first step of the CNC milling process is to create 3D (or 2D) drawings of your desired part using CAD/CAM software like Autodesk Inventor, Fusion 360, and SolidWorks. These computer-aided design (CAD) or computer-aided manufacturing (CAM) tools allow you to specify your dimensions and tolerance requirements.

The first step of the CNC milling process is to create 3D (or 2D) drawings of your desired part using CAD/CAM software like Autodesk Inventor, Fusion 360, and SolidWorks. These computer-aided design (CAD) or computer-aided manufacturing (CAM) tools allow you to specify your dimensions and tolerance requirements.

Stage 2 Convert the CAD Model to a CNC program

Export your CAD model into a CNC-compatible file using the CAM software we mentioned in stage

- CAM tools have functionalities that allow you to convert your 3D CAD model into a computer program called G-code.

The G-code then automates all the actions necessary to fabricate your part, for example, the cutting sequence, toolpath, machine tool speed, workpiece movement, to name a few.

Stage 3 Setup the CNC Milling Machine and Execute Milling Operation

This is the phase where you insert your workpiece into the CNC machine work surface, attach your cutting tools into the spindle of the CNC machine, and download the G-code you already created in once all these steps have been completed, proceed to initiate the machining program. And the milling machine will perform all operations needed to turn your workpiece into your desired part.

This is the phase where you insert your workpiece into the CNC machine work surface, attach your cutting tools into the spindle of the CNC machine, and download the G-code you already created in once all these steps have been completed, proceed to initiate the machining program. And the milling machine will perform all operations needed to turn your workpiece into your desired part.

3 Common CNC Milling Operations

Following are some of the most common milling operations used today.

Face Milling

Face milling is arguably the most common type of milling operation used for creating flat surfaces. This machining operation is done such that the rotating axis of the cutting tool is perpendicular to the surface of the workpiece being machined.

As the name suggests, face milling operation involves the use of a face mill cutter. These cutters have multiple interchangeable cutter inserts, allowing you to produce your desired surface efficiently in one pass.

Compared to peripheral milling, face milling can also help you achieve higher-quality surface finishes. This is because the design of the face mill cutter gives you close control of the machining operation, allowing you to remove a smaller amount of material compared to peripheral milling.

Plain Milling

Plain milling, also called slab milling, is a milling operation used to produce plain, horizontal surfaces. The machining operation is done such that the axis of the cutting tool is parallel to the surface being machined.